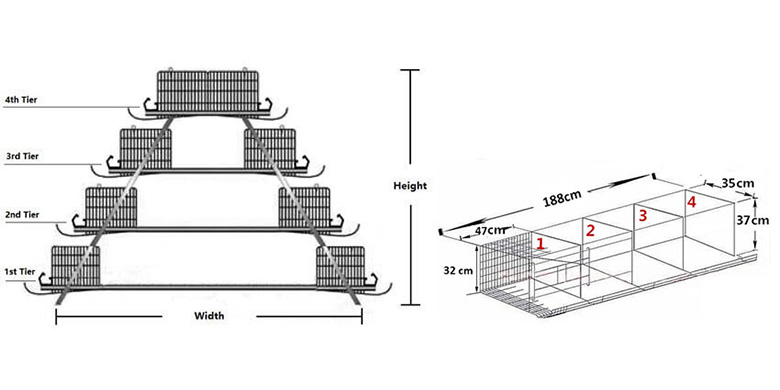

| Specification | Overview |

Battery Cage System Model No. designation:

"A" – A shape;

"A" – A shape;

"34" – 3 tiers 4 nests (doors);

"34" – 3 tiers 4 nests (doors);

"L" – Large size

"L" – Large size

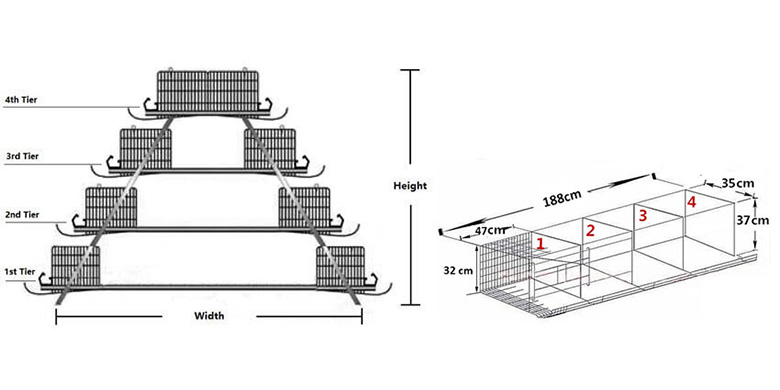

| Model | Overall size (L x W x H) | Nest per strip | Total nests (doors) | Size of the nest | Chickens/nest | Capacity (Birds/Set) |

| HT-A34 (Hot sale) | 1.88 x 2.1 x 1.5 m | 4 | 24 | 0.47 x 0.35 x 0.37 x 0.32 m | 4 | 96 |

| HT-A45L (Hot sale) | 2.15 x 2.4 x 1.95 m | 5 | 40 | 0.43 x 0.38 x 0.38 x 0.33 m | 4 | 160 |

| HT-A34-Half | 1.88 x 1.1m x 1.5 m | 4 | 12 | 0.47 x 0.35 x 0.37 x 0.33 m | 4 | 48 |

| HT-A34L | 2.0 x 2.1 x 1.5 m | 4 | 24 | 0.50 x 0.38 x 0.38 x 0.33 m | 4 | 96 |

| HT-A35L | 2.15 x 2.1 x 1.5 m | 5 | 30 | 0.43 x 0.38 x 0.38 x 0.33 m | 4 | 120 |

| HT-A44 | 1.88 x 2.4 x 1.95 m | 4 | 32 | 0.47 x 0.35 x 0.37 x 0.32 m | 4 | 128 |

| HT-A44L | 2.0 x 2.4 x 1.95 m | 4 | 32 | 0.50 x 0.38 x 0.38 x 0.33 m | 4 | 128 |

| Material | Low carbon steel Q235 | |||||

| Surface Treatment and Service Life | Electro galvanized, Zinc coating ≤ 8 g/m2, (7-10 years); Hot-dip galvanized, Zinc coating: ≤ 275 g/m2, (15-20 years); PVC coated (7 years) Notes: The service life depends on the surrounding environment. |

|||||

What is a layer chicken cage?

What is a layer chicken cage?

A layer chicken cage is a kind of poultry cage, also known as battery cage system, which is used for rearing egg-hens after the day old chick grown to 20 weeks, it is used in chicken farm to increase egg production.

Why choose layer chicken cage?

Why choose layer chicken cage?

The biggest advantage of layer cage is that they effectively increase egg production. It is convenient for centralized management, reduces labor and labor costs, saves land area, and improves production efficiency.

How to choose the chicken farm equipment you need?

How to choose the chicken farm equipment you need?

1- If you have less than 2,000 layer chickens we advise you to only buy poultry cage. Drinking system is automated, but workers need to feed the chicken manually, as well as collect the eggs, and remove the droppings.

2- If you have 5,000 – 10,000 chickens we suggest you purchase the manure removal machine as well as battery cages. By removing the droppings timeously, you will reduce the possibility of disease and improve the egg production rate, at the same time saving even more time and labor costs. The scraper type manure removal machine is the most economical type. A semi-automatic chicken feeding machine is also necessary for this quantity of chickens. It is small and costs less than a fully automatic chicken feeding machine, and because it uses a battery cage, you will avoid the inconvenience of power failures. You can feed 10,000 chicken in just half an hour, and save a lot on labor.

3- If you have more than 10,000 layer chickens you may need to get fully automatic equipment including battery cage, automatic chicken feeder, automatic egg collector, as well as manure scraper (automatic manure removal system). If the scale of your operation exceeds 50,000 chickens, you will need a feed silo. For less than 50,000 chickens you can just use one screw conveyor to convey the food to the hopper. If you want to build a closed system, you need to know that an exhaust fan and cooling pad are necessary environment control equipment items. If you use an open system and the weather is hot, you can use a fogger.